Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

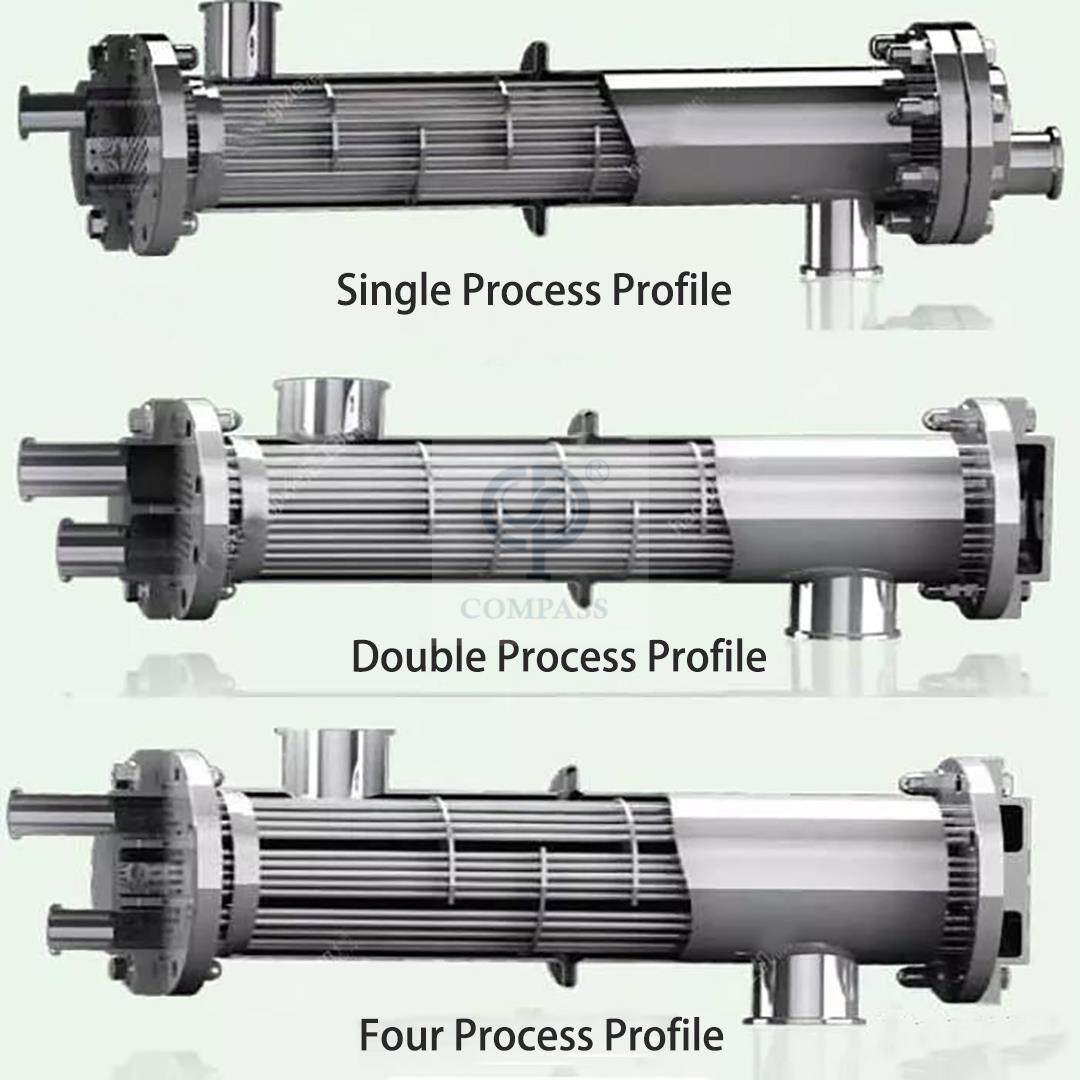

The stainless steel tuber heat exchanger seamlessly integrates the remarkable properties of stainless steel to deliver unrivaled performance and unwavering reliability. With its state-of-the-art design and construction, this tuber heat exchanger surpasses industry standards, offering unparalleled heat transfer capabilities that cater to a diverse array of industrial, commercial, and residential applications.

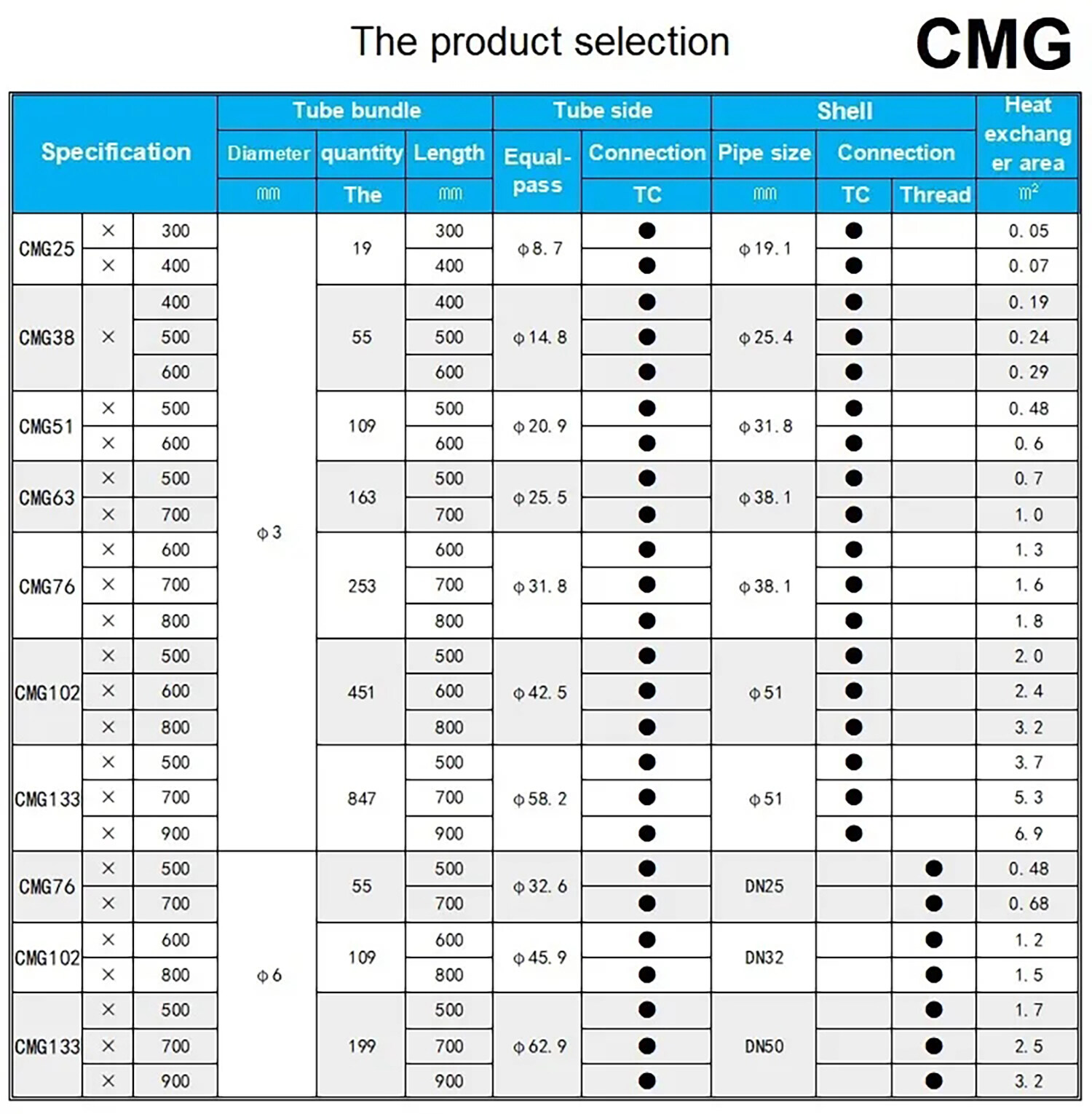

Product parameter

| Commodity | Tube Plate Heat Exchanger | |

| Type of Tube Plate Heat Exchanger | Double Tube Plate Heat Exchanger | |

| Single Tube Plate Heat Exchanger | ||

| Material Contact Parts | SS304(1.4301)/SS316L (1.4404),SS2205, SS2507 | Provided with material inspection report |

| Material Non-contact Parts | SS304(1.4301) | |

| Sealing Material | NBR,EPDM,Silicone,FKM. All material comply with FDA21CFR117.2600 | |

| Flow | 30-32000L | |

| Heat Transfer Area | 0.05m², 1.0m², 1.5m², 2.0m², 2.5m², 3.0m² | |

| Tube Size | 6mm, 8mm, 10mm, 12mm, 14mm, 16mm, 19mm ,25mm etc | |

| Heat Transfer Coefficient | Water - Water : 1100~1400W/(m2 ℃) | |

| Water -Steam : 2300~5700W/(m2 ℃) | ||

| Connection | Union, Internal Thread, Tri-clamp, Flange | |

| Max. Pressure | 10bar (145psi) | |

| Workingl Pressure | 0-6bar (0-87psi) | |

| Design Temperature | 14 ~ 392°F (-10ºC~+200 ℃) | |

| Internal Surface Finish | Ra<0.5μm | |

| Installed Position | Vertical, Horizontal | |

Feature of Tuber Heat Exchanger:

Good Strength and Durability: Renowned for their exceptional strength and durability, stainless steel tubes stand as a testament to engineering excellence. These tubes exhibit an extraordinary capacity to withstand the most demanding conditions, including high temperatures and pressures, without succumbing to deformation or failure. Their robust construction and inherent resistance to corrosion make them an ideal choice for industries that require unfaltering performance and longevity.

Good Hygienic Properties: Renowned for its impeccable hygiene standards, stainless steel emerges as the material of choice for applications in the food and pharmaceutical industries, where uncompromising cleanliness is paramount. Its inherent properties, including non-porous surfaces and resistance to bacterial growth, ensure a pristine environment that meets the stringent requirements of these industries.

Makes Long Service Life to be Used with Many Years: Through meticulous maintenance and attentive care, stainless steel tube heat exchangers can boast an extended service life, offering unwavering heat transfer performance that endures for countless years. With a steadfast commitment to longevity, the tuber heat exchangers exemplify resilience and reliability, consistently delivering optimal thermal efficiency throughout their operational lifespan.

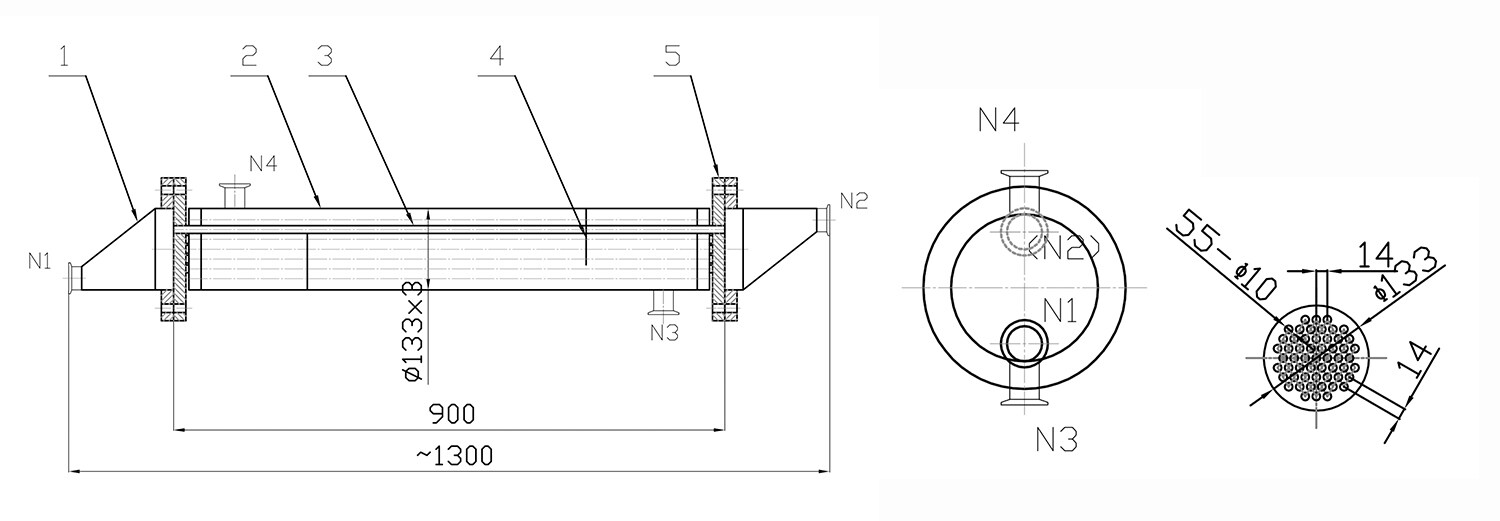

Product drawing

Advantages of Tuber Heat Exchanger:

Strong Ability to Withstand High Temperature and Pressure: Exemplifying the pinnacle of engineering ingenuity, meticulously designed and flawlessly manufactured tuber heat exchangers exhibit an extraordinary ability to withstand the most extreme conditions. These exceptional heat exchangers effortlessly endure high temperatures, pressures, and even corrosive fluids, all while maintaining their structural integrity and ensuring an extended service life.

Cost-Effective Tuber Heat Exchanger: Tuber heat exchangers present a compelling cost-effective solution for diverse heat transfer requirements. Notably, the manufacturing and installation costs associated with these exchangers are often significantly lower compared to alternative options, making them an economically prudent choice for industries seeking optimal thermal management solutions.

Various Customization to Meet Your Specific Needs: Tuber heat exchangers can be meticulously tailored to meet precise specifications, encompassing a wide array of factors such as size, material composition, and design configurations. This bespoke approach ensures not only optimal performance but also seamless compatibility with the intended application.

Application scenario